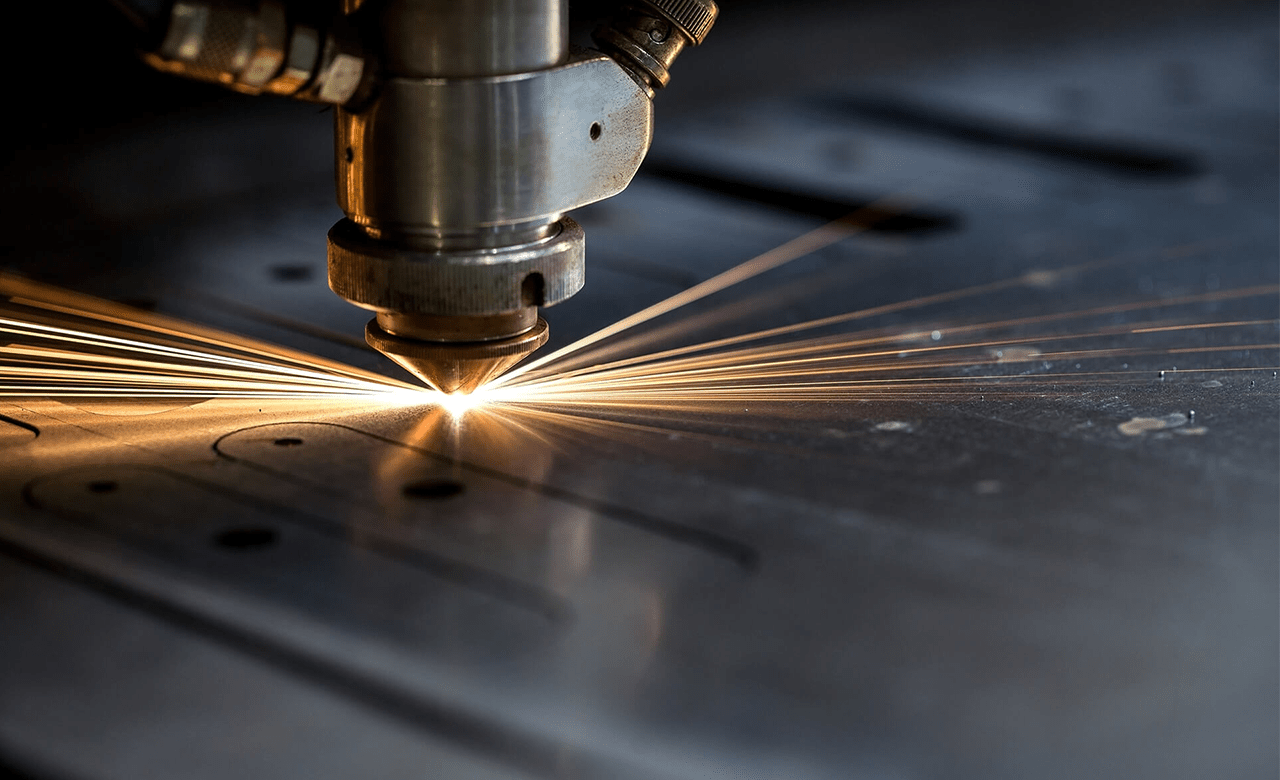

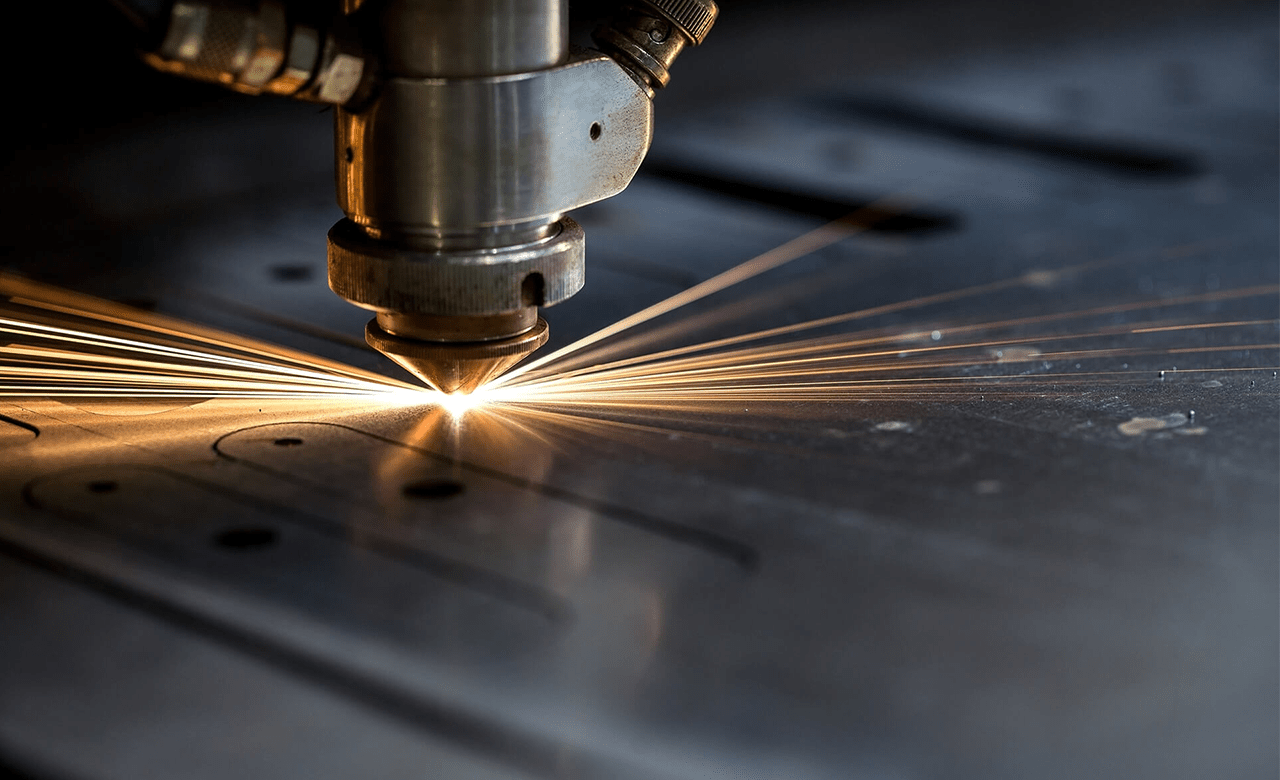

Laser and plasma cutting are both fabrication processes used to cut the material into custom and complex shapes and designs. Plasma and laser cutting can produce hazardous byproducts in manufacturing processes, which dust collection equipment can help remove. Whether you are using a plasma with a conductive gas and a torch head or a high-power laser to cut that material, both processes produce highly toxic fumes and gases.

The need for an efficient dust collector in these applications is very high. Employers must place emphasis on employee health due to high levels of exposure to these harmful air pollutants. Source capture is the most effective way to collect these harmful pollutants. Custom hood enclosures or capture hoods work well and must be designed properly to ensure efficiency.

Pollution Control Systems only carries reliable DeGATECH DEGA-PRO fume collectors to help efficiently eliminate dangerous levels of fumes and gases in laser and plasma cutting applications. Our selection of equipment can improve air quality in your facility while requiring minimal maintenance. You can benefit from a system of machinery that serves your facility for many years with consistent results. Here are some of the machines we offer for dust collection in laser and plasma cutting applications.

DeGATECH DEGA-PRO Dust Collectors for Plasma and Laser Cutting keeps employees safe and maintain consistent airflow in your facility, consider installing a system of DeGATECH dust collectors in laser and plasma cutting facilities. Our pollution control experts can help you determine which equipment will work best in your facility and design a system that gives you consistent results. All of the equipment we offer can improve cutting environments, serving as an integral part of your operations and keeping employees safer.

To receive more information about DeGATECH dust collectors for plasma and laser cutting facilities or other types of applications, contact Pollution Control Systems. We offer a free evaluation of your facility to determine how our selection of equipment can improve your facility.

In some ways, laser cutting is a safer metalworking process than many others. Sure, there is a high-powered laser involved, but the process is fast and hands-off. However, the dust created by laser cutting is a serious inhalation hazard. The intense heat involved in the process creates particulates in the sub-micron size; the smaller the particulate, the easier it is inhaled and absorbed into the body.

[read_more id=”1″ more=”Read more” less=”Read less”]Because metal cutting produces metallic dust, the process is especially dangerous. Dusts might include metals such as chromium, lead, nickel, cadmium and others. These dusts are so dangerous the Occupational Safety and Health Administration (OSHA) has issued separate worker exposure limits for each one. Some of these metals have been implicated in cases of cancer and other serious diseases.Fine metallic dusts can be an ignition hazard, as well. If certain metallic dusts accumulate in an enclosed space and interact with water, they can produce hydrogen and lead to an explosion. Dust explosions injure or kill many workers, every year.

Laser & Plasma cutting dust causes other problems, as well. While not a health issue, the impact of dust on cutting efficiency is a serious concern. Dust from laser cutting can be so thick that it can diffuse the beam. This reduces the intensity of the beam and can interfere with the process. Also, maintenance costs for these processes can rise if dust is not extracted properly.

DEGA-PRO Series offers:

Oval Filters make filtration more efficient, compact and cost-effective than ever before. Only available from DeGATECH, the new DEGA-PRO 3 and DEGA-PRO 4 collectors are expertly engineered with our proprietary high performance oval-shaped cartridge filters and MicroDEN Nano-Web filter media to provide the most efficient, easy-to-maintain filtration systems in footprints that conserve valuable manufacturing floor space. Equipped with an integral high efficiency spark trap and Drop-Out Design for fume collection and easily adapted for dust collection applications, DEGA-PRO is the most reliable and versatile collector for the laser & Plasma cutting market. And no other collector is as easy to install and maintain, making DEGA-PRO the best collector to complete a production system.

For innovative filtration, turn to the PRO. DeGATECH’s DEGA-PRO . No other collector combines high performance technology with a compact design to deliver unparalleled filtration efficiency and value. Increased airflow capacity lets you drop down a size in the collector while maintaining capacity or increase airflow with a same-sized collector. Designed with hinged-door access to filters on two sides, DEGA-PRO fits into corners, requires no extra wiring and easily connects to ductwork.

MERV 15, Efficiency Oval Cartridges Developed using computer-modeling technology, DeGATECH’s unique oval-shaped cartridge filters provide more airflow capacity and last longer than traditional Flat cartridge filters. Airflow modeling software revealed that oval-shaped cartridge filters have fewer areas of high velocity , resulting in a lower potential for media abrasion and increased filter life.

Standard Features for DEGA-PRO 3 and DEGA-PRO 4

Depending on the size of your facility and the level of hazardous dust your operations produce, DeGATECH Engineering team can design and install a system of dust collectors to reduce this risk and maintain employee health. Our dust collectors require minimal maintenance, with lower initial purchase prices.